钢铁行业如何应对气候变化带来的挑战?

钢铁行业通过降低全行业的能耗及排放强度以应对气候变化带来的全球挑战

钢铁行业采取各项技术解决常见的排放问题(如硫氧化物、氮氧化物、粉尘、重金属等),以应对愈加严苛的法规要求。

钢铁行业依赖碳还原铁矿石,并制造还原过程发生所需的温度,因此二氧化碳排放问题仍是钢铁行业面临的问题,高炉工艺在过去几年中已经得到改进,随着智能制造的发展,将变得更加高效。

目前行业面临的四大挑战是:

- 确保炼铁工艺使用的原料达到最少化(铁矿石、炼焦煤),并实现资源效率最大化

- 钢铁行业通过最佳实践的转让,降低脱碳处理中的能源强度,以减少二氧化碳的排放。多家钢铁企业实践证明,能源强度影响因子多,但都可控

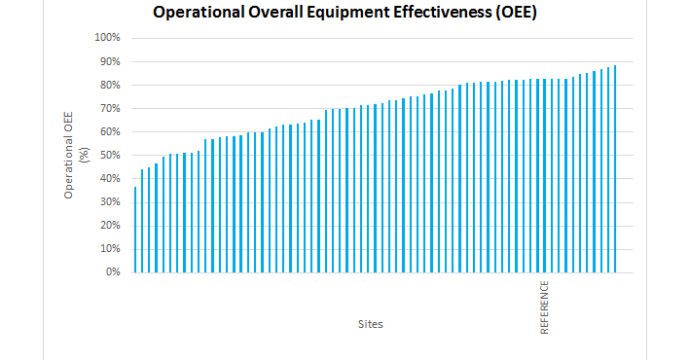

这张图表显示典型运行工厂的可靠性绩效及接近参考水平的最佳运行工厂

- 在能源强度最密集的工艺尽早推进工业4.0、智能制造。数据显示智能控制系统能降低变量从而使工艺运行更加稳定和高效,这对所有工艺都是一样的。当务之急是对能源密集型的工艺引进工业4.0,以取得最大的成效

- 加快投资开发突破性技术以应对二氧化碳减排的迫切需要。现有的突破性技术及项目包括:超低二氧化碳排放炼钢工艺(ULCOS)、在ULCOS基础上开发的熔融还原工艺(HIsarna)、日本的创新炼铁工艺技术开发项目(COURSE50)、美国钢铁协会发起的项目、韩国浦项制铁投资的项目、中国台湾中钢及宝武钢铁集团发起的项目。

近期,有两个使用氢取代碳作为还原剂的项目已启动,前景非常看好,分别是瑞典钢铁公司发起的Hybritt和奥钢联发起的H2F,其工艺的还原反应迅速,需要更多能源产生热量(1300-1500度)及生成氢气,这意味着用于加热的能源(如电能)及生成氢气过程必须是无碳,才能有效减少炼钢过程中的二氧化碳排放强度。

上述新项目致力于应对气候变化的挑战,以实现将全球升温控制在2度以内。

为了推进突破性技术的研究和发展,需要投入资金以支持研究团队的工作,但不能仅依靠钢铁行业自身来筹集。来自政府和当地金融机构的支持(尤其是跨境政府的支持)才能有效推进技术的开发。

与此同时,若社会希望实现将全球升温控制2度以内,必须通过碳捕获利用和储存技术来储存二氧化碳,或将二氧化碳用于其他领域,直至更高效突破性技术得以开发。

在中国,评论区无法使用。我们正在寻求解决方案,很抱歉给用户带来不便。