气候变化:提高能源效率

世界钢铁协会的会员企业致力于投资开发突破性技术,并将 2050年定为共同目标,力求实现重大突破,这促使人们将关注点投向未来的30年。

那么,从现在到2050年,钢铁行业还有哪些领域具有改进潜力呢?

世界钢铁协会会员企业的粗钢产量占全球粗钢产量的80%以上,一直积极寻求各种解决方案以提高能源效率及优化产品设计。在通往实现突破性技术的道路上,在中短期内,通过提高工艺效率将有助于改善气候变化。

近期,世界钢铁协会会员企业同意启动名为“能效升级”的行业级改进项目。该项目涵盖原料、能源输入、工艺收得率以及设备维护多个流程,通过改进流程可使钢厂的能源效率达到钢铁行业优秀企业的效率水平。

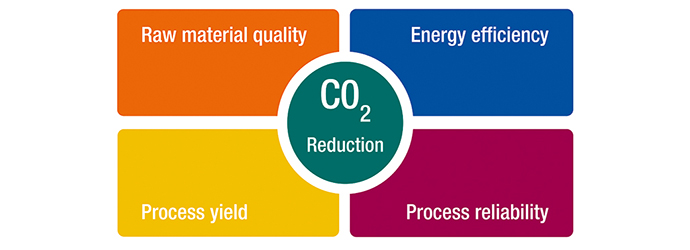

根据优秀企业的先进做法,制定了“四步走”的审核流程,利用下列四个关键性指标,供所有厂区经营者参照执行。

- 原料优化选采与使用:铁矿石与炼焦煤的品位对于能源强度和二氧化碳排放具有直接影响。通过从源头选矿和选煤、改用低碳或含氢燃料以及增加碱性氧气转炉的废钢利用率等措施,将有效显著提高生产效率。

- 提高能源效率,减少废弃物:提高能源效率是改善资源效率的关键,这里列举几个经过测试和证明有效的改进措施:从固体和气体流中回收热量或能源、干熄焦、热电联产机组、节电措施(旨在自给自足)等。

- 提高工艺收得率:工艺收得率的提高将使钢铁生产过程中的产量增加,并降低能源强度和原料的使用量。

- 提高工艺可靠性:加强钢厂的设备维护,确保了设备运行可靠性,可减少质量和工艺时间损失,从而降低每吨钢材的能耗。

基于先进做法制定的效率审核流程将面向世界钢铁协会会员企业开放。2019年,该项目将在9个厂区进行测试;2020-2025期间,该项目将在更大范围内开展。

我们邀请全体会员企业积极参与该项目,并且希望所有地区都有高水平的参与。2020-2021年间,我们将提供该项目的进度审核报告,供会员企业参考。