钢铁行业的共生产品

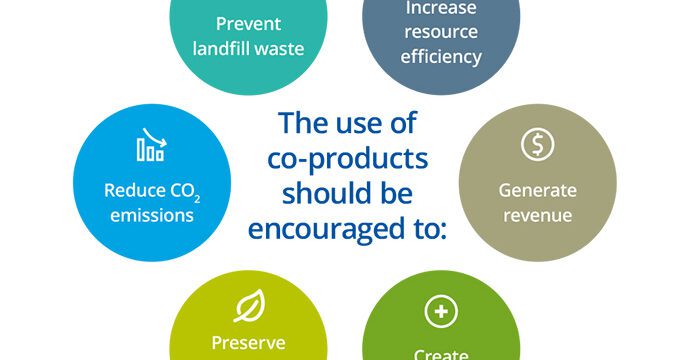

立法应鼓励钢铁行业共生产品的可持续性使用。

在过去的20年中,钢铁行业的共生产品使用量大幅增加。随着创新技术的发展及与其他行业的密切协作,钢铁行业非常接近废料零填埋的目标。

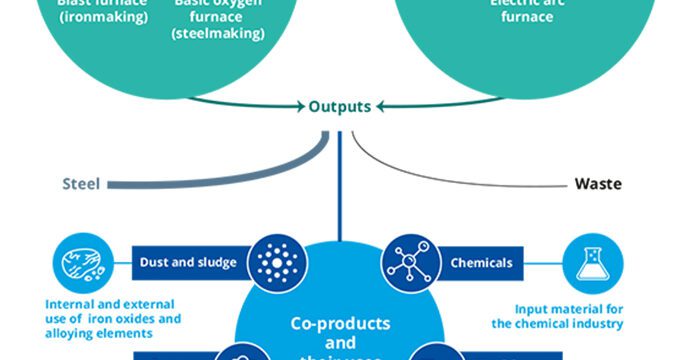

在生铁和粗钢生产过程中产生的主要固体共生产品是炉渣(按质量计占90%)、粉尘和尘泥。

平均而言,电弧炉(EAF)路线生产一吨粗钢约产生200千克的共生产品,高炉 – 转炉(BF-BOF)路线约产生400千克的共生产品。

除固体共生产品外,焦炉、高炉或转炉的工艺煤气也是重要的炼钢共生产品。

共生产品定义:共生产品是指与核心产品同步生产或者是伴随核心产品产生并具有潜在价值的材料。

钢铁行业共生产品的利用

钢铁行业的共生产品可在本行业内、其他行业或社会上进行广泛地利用。在一些情况下,共生产品的物理特性决定其用途,例如,炼钢炉渣可以用做道路建设的骨料,而共生产品的化学成分有时也决定其用途,如工艺煤气可用做燃料以产生热量或电力。在浓度足够的情况下,还可以从炉渣、粉尘及尘泥中回收贵重有色金属。

钢铁行业共生产品常见用途:

- 高炉渣 – 替代水泥制造中的熟料

- 炼钢炉渣 – 道路建设中的骨料,土壤改良

- 工艺煤气 – 供热和发电

- 粉尘和尘泥 – 供钢厂内部使用的氧化铁和合金元素

- 炼焦产生的焦化产品 – 化工用的焦油、氨、苯酚、硫酸和萘

- 来自工厂的乳剂和废油-用作高炉还原剂及被焦化厂所利用

- 在所有情况下,使用钢铁共生产品作为可替代原材料,有助于提高资源效率,为发展循环经济做贡献。

当前的技术发展

为了提高共生产品的品质,钢铁行业持续不断在生产和加工阶段寻求技术发展以提高共生产品的利用率,更重要的是通过提高可回收共生材料的品质扩大其利用范围。

最近,在需求端的管理及重新关注生产阶段以更好控制共生产品的品质已取得一些进展。

公众和政府意识

当前,共生产品尚没有统一的法律定义,各国的立法有所差异。当共生产品与废弃物没有明确区别时,将给共生产品的使用和运输,以及公众和政府对共生产品的认识都造成了不必要的障碍。

监管框架

炼钢共生产品使用优势在于生产同等产品的前提下,节省能源、减少排放。因此,应优先并鼓励尽量使用共生产品。

世界钢铁协会相信,用共生产品替代同等产品在现有的相同法律框架下应该是可行的,其法律框架应该包括同等质量材料的应用、环境测试要求及对初级和二级材料的限制等。例如,道路建设中使用的炉渣的渗滤液水平决定其可用做不同地质的天然骨料。

此外,制定共生产品应用的国际及区域质量标准,以增强公众和政府的意识,也是一种推进方式。

- 应鼓励使用共生产品,从而节约自然资源和能源。

- 宜立法规定优先使用副产品,或至少尽量降低副产品使用门槛。

- 法律框架应鼓励使用工艺气体,以节约化石燃料、减少因气体放散产生的二氧化碳排放。

循环经济,资源效率和零废弃

共生产品的充分利用促使钢铁行业的全球材料效率达到96.3%(全行业效率的平均值)。我们的目标是100%有效地使用原材料和实现零废弃。

共生产品可在炼钢过程中重复利用或出售供其他行业使用。这可以提高资源效率,防止垃圾填埋并减少二氧化碳排放。共生产品的销售在经济上也是可持续的,它为钢铁生产商创造了收入,并在全球范围内形成切实可行的行业基础。

实现可持续循环经济的关键在于尽量减少废弃,并确保资源的使用周期尽可能延长。

例如,在混凝土中用矿渣水泥代替硅酸盐水泥可以节省用于混凝土及其替代材料的生产所需要的高达59%的二氧化碳排放和42%能源。

- 在利用共生产品管理方面需要从全局考虑,环境、能源和资源等所有方面都要予以考虑。

- 须大力支持通过立法推动共生产品的利用,并应倡导开发共生产品的新应用。

- 应该鼓励钢铁行业与当地社区建立伙伴关系,因为钢铁行业可以通过向当地社区提供工艺煤气、蒸汽或余热,成为可靠的合作伙伴。

研究

为推动钢铁行业的共生产品得以充分利用,并取得最大的收益,正在持续进行对工艺、加工和应用的研究。

例如,在碳捕捉和使用(CCU)领域正在开展研究,未来能够捕捉工艺气体和化工业等后续使用过程中的二氧化碳。

而且,钢铁业将因与其它工业部门建立伙伴关系及政府支持中极大受益,取得进一步进展。

这也会增加决策者的认识,且有希望启动必要的法律框架讨论。

- 对共生产品新应用的研究将从政府不断增加的支持中大大获益。

钢铁行业的共生产品及其使用

关于共生产品使用范例,可查看期刊的PDF格式文件。